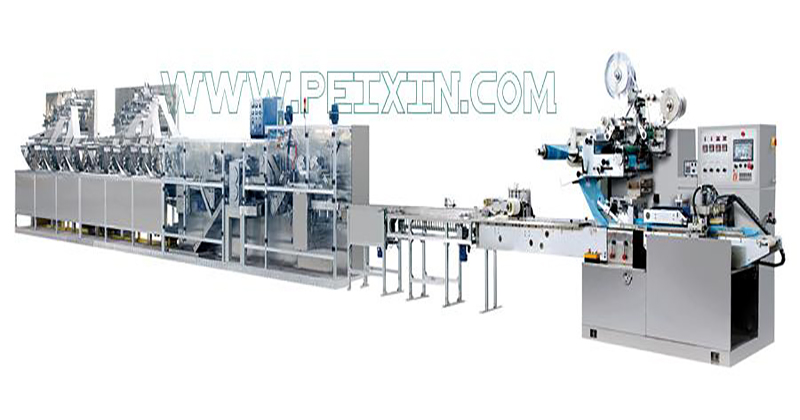

Renewable Design for Servo Control Diaper Machine - Full Servo Control Pull-ups Baby Panty Production Line – Peixin

Renewable Design for Servo Control Diaper Machine - Full Servo Control Pull-ups Baby Panty Production Line – Peixin Detail:

Model:PX-LLK-600-SF、PX-LLK-550-BSF

Equipment Function & Parameter

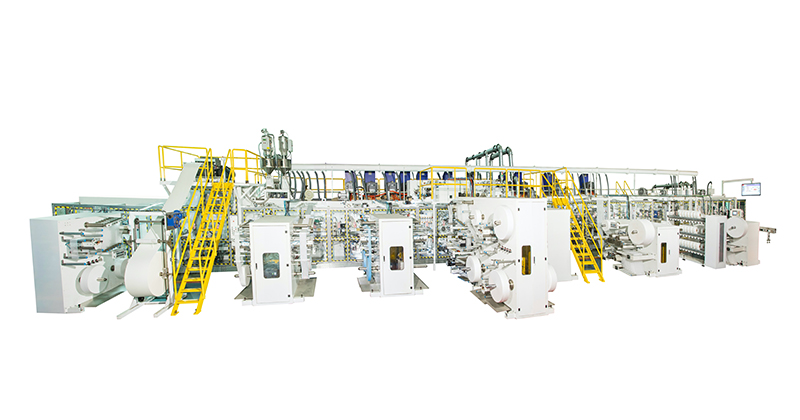

1. Full-servo auto-controlling system with high automation while the machine can be also upgraded as per customers’reasonable requirement.

2. Under European CE standard designing, passed the CE certificate, Electric parts under CE or UL quality certification, with safety protection unit, such as, safety door and emergency stop and so on.

3. Most of the spare parts are under numerical control precisely processing, Key mechanical parts are under CNC processing, Main outsourcing parts are World famous brand.

4. Operating interface is the industry PLC with humanistic designing and optional collection for production record.

5. It is workable to mount the camera monitoring system, which can conduct on-line size checking, location inspecting, missing inspecting, stain spot scanning and so on..

6. Other optional functions can be chosen by customers’ requirement:

a. Full servo control stacker(Auto Bagging Machine)

b. Automatic bagging sealing machine

Parameters

Output products from this machine:XL,L,M,S pull-ups baby diaper

Design speed:600pcs/min

Stable production speed (according to M size): 500pcs/min

Overall size(L×W×H):30mx7mx3.4m(With stacker)

Total power(exclude glue applicator and air compressor):300KW(380V,50HZ)

Weight:About 100 Ton

Can be with full servo control stacker(Auto Bagging machine), production speed 50 bags/Min

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is definitely the persistent conception of our corporation to the long-term to establish alongside one another with customers for mutual reciprocity and mutual profit for Renewable Design for Servo Control Diaper Machine - Full Servo Control Pull-ups Baby Panty Production Line – Peixin , The product will supply to all over the world, such as: Kyrgyzstan, Costa Rica, New York, By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.