Best quality Mini Pad Production Line - Full Servo High-speed Toilet Paper / Kitchen Towel Automatic Packaging Production Line – Peixin

Best quality Mini Pad Production Line - Full Servo High-speed Toilet Paper / Kitchen Towel Automatic Packaging Production Line – Peixin Detail:

Model:PX-RW300(1575/2200/2800)

Equipment Function & Character

1. Under European CE standard designing, Passed CE certificate, With CE or UL certificate for Electric Parts and with safety device, such as, emergency stop and so on.

2. Most of parts are precisely processed by numerical-control machine; the key mechanical parts are under CNC processing; while the main outsourcing parts are world famous brand.

3. This machine adopts advanced servo driving, PLC system and touching-screen operating system. This machine can materialize successive production (without stop machine), stable running and high production efficiency.

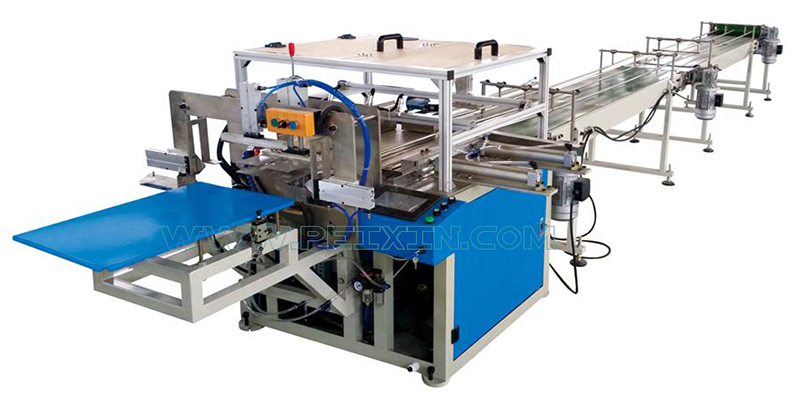

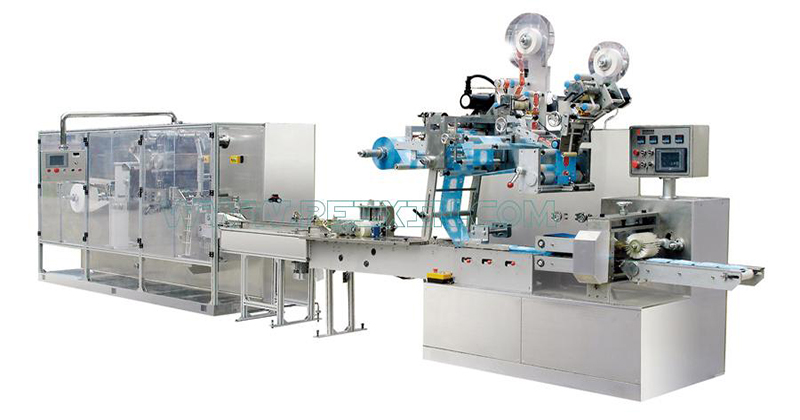

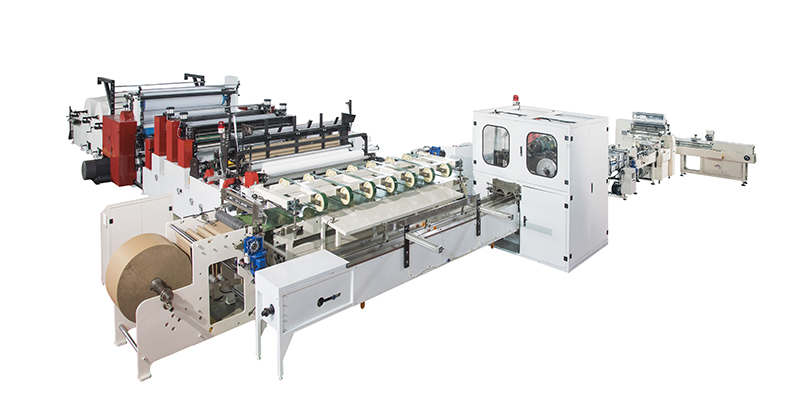

4. This equipment is consisting of rewinding & perforating machine, conveyer, log accumulating system, cutting machine and packaging machine.

5. Complete Production Line Size:L×W×H =20000×8000×3040 mm

Parameters

| Rewinding machine | High-speed roll cutting machine | Log Accumulating Machine | Chosen Items | |||

| Jumbo roll width | 1800mm-2800mm | Model | LC150(2200) / LC150 (2800) | Model | 2200 / 2800 | Customers can order below-mentioned auxiliary parts as per option: 1. Two or three jumbo roll stands 2. Steel to steel embossment, steel to rubber embossment, and steel to paper roller embossment 3. 1-2 color printing units. |

| Jumbo roll outer diameter | Φ2m (other sizes can be ordered) | Toilet roll length | ≤2200mm / 2200mm<L<2800mm | Toilet roll length | ≤2200mm / 2200mm<L<2800m | |

| Jumbo roll core inner diameter | 3 inch (76mm)(Other sizes can be ordered) | Channel | Two Channels | Toilet roll diameter | Maximum 150mm, Minimum 90mm | |

| Machine speed | 300m/min | Toilet roll diameter | Φ90mm-Φ150mm(tandard size: 110±5mm) | Effective roll storage quantity | 130PCS Ordered by customers | |

| Stable machine speed | 260m/min | Cutting length | 60-300mm(length is changeable, servo control) | Storing speed | 25rolls /min | |

| Finished products outer diameter | Maximum 150mm, minimum 90mm | Tolerance of finished products | ±1mm | Installed power | 2.2KW | |

| Perforation Distance | 4 cutting 90-180mm 2 cutting 180-360mm Adjustable | Machine speed | 120cuts/min, 2 rolls/cut | |||

| Finished roll core inner diameter | Maximum 50mm; Minimum 38mm | Blade Sharpening System | Blade Sharpens automatically, touching-screen sets parameter |

|||

| Jumbo roll material | 14-30 GSM toilet paper or kitchen towel | Blade Diameter | Φ610mm | |||

| Installed power | 65KW(set as per model) | Installed power | 12KW | |||

| Control system | PLC system | |||||

| Servo motor | Japan Mitsubishi | |||||

| Parameter set | Touching-screen system | |||||

| Driving | Timing belt flat belt | |||||

Product detail pictures:

Related Product Guide:

We believe that long term partnership is a result of high quality, value added service, rich experience and personal contact for Best quality Mini Pad Production Line - Full Servo High-speed Toilet Paper / Kitchen Towel Automatic Packaging Production Line – Peixin , The product will supply to all over the world, such as: Bangladesh, Sevilla, Belgium, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality solutions. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our items and services, please do not hesitate to contact us!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!