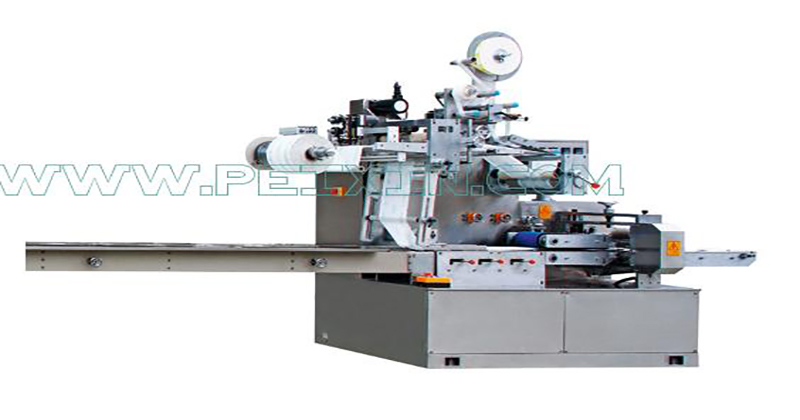

5-20 Pieces Wet Tissue Packaging Machine

Model:PX-SJZ-BZ20

Equipment Function & Character

1. Machine is covered with stainless steel board, while the mechanical parts contacting on products are made by stainless steel. Appearance is beautiful while hygiene of products is protected, reaching to the international request on wet-wipe production equipment.

2. Under European CE standard designing, Passed CE certificate, With CE or UL certificate for Electric Parts and with safety device, such as, safety-guard door, emergency stop and so on.

3. Most of parts are precisely processed by numerical-control machine; the key mechanical parts are under CNC processing; while the main outsourcing parts are world famous brand.

4. It can package wet wipe with air-laid paper or N.W..

5. This machine adopts full digital centralizing control, such as, advanced servo system, PLC program, touching screener and so on; it is accurate in positioning.

6. Production date printing—Open hole molding—label sticking—Package forming—Package feeding—Central sealing—Full-automatic on longitudinal cutting and side cutting.

7. Mounting with differential device to make adjustment on material feeding location without stopping machine.

8. Full-servo three-point position guide-flow, auto pointing and coordinating, double-servo horizontal sealing and positioning control, with optional duplex path horizontal sealing machine.

9. Add queueing unit and stacker in front, easier to operate, fast.

Parameters

Packaging size:L×W×H = 90~200×70~90×5~30(mm)

Production speed: 60~80 pcs/min (standard pieces: 10 pcs/min)

(with 2 sets of PX-SJZ-BZ20 Full-automatic folding machine or use the robot hand to connect the machine, speed can be improved double)

Machine power:5.0kw (380V, 50Hz)

Overall size:L×W×H = 7.5m×1.8m×1.8m